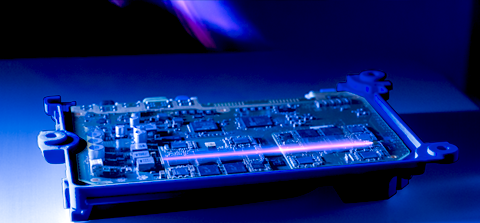

Precision down to the smallest detail

High-precision production lines for the electronics of the future

The automation of current-carrying and signaling components in the automobile is one of the core competencies of M.A.i. Our systems are developed with the highest precision in order to meet both the strict requirements for technical cleanliness and the individual process requirements of our customers.

With our many years of expertise, we have already successfully implemented hundreds of automation solutions – from the engine compartment and electrical engineering to interior and exterior areas, the vehicle body and the interior. Rely on customized solutions that combine quality and efficiency in your production.

Material flow and assembly systems

Integration of product carrier circulation systems, assembly rotary indexing tables as well as separating and press-fit stations for printed circuit boards in the end position.

Assembly and joining technologies

Implementation of a wide range of assembly and riveting processes, motor assembly and automatic screwing stations.

Special processes

Non-contact greasing, precise laser welding and DMC laser marking for maximum accuracy.

Process data management

Seamless acquisition of all process data with SCADA software programs and IPC solutions as well as seamless integration into customer software platforms.

Camera-based quality inspection

Carrying out various camera inspections to ensure product quality.

End-of-line test stations

Fully automated electrical, mechanical and optical final tests, supplemented by noise measurements and dynamic measurement procedures on request.