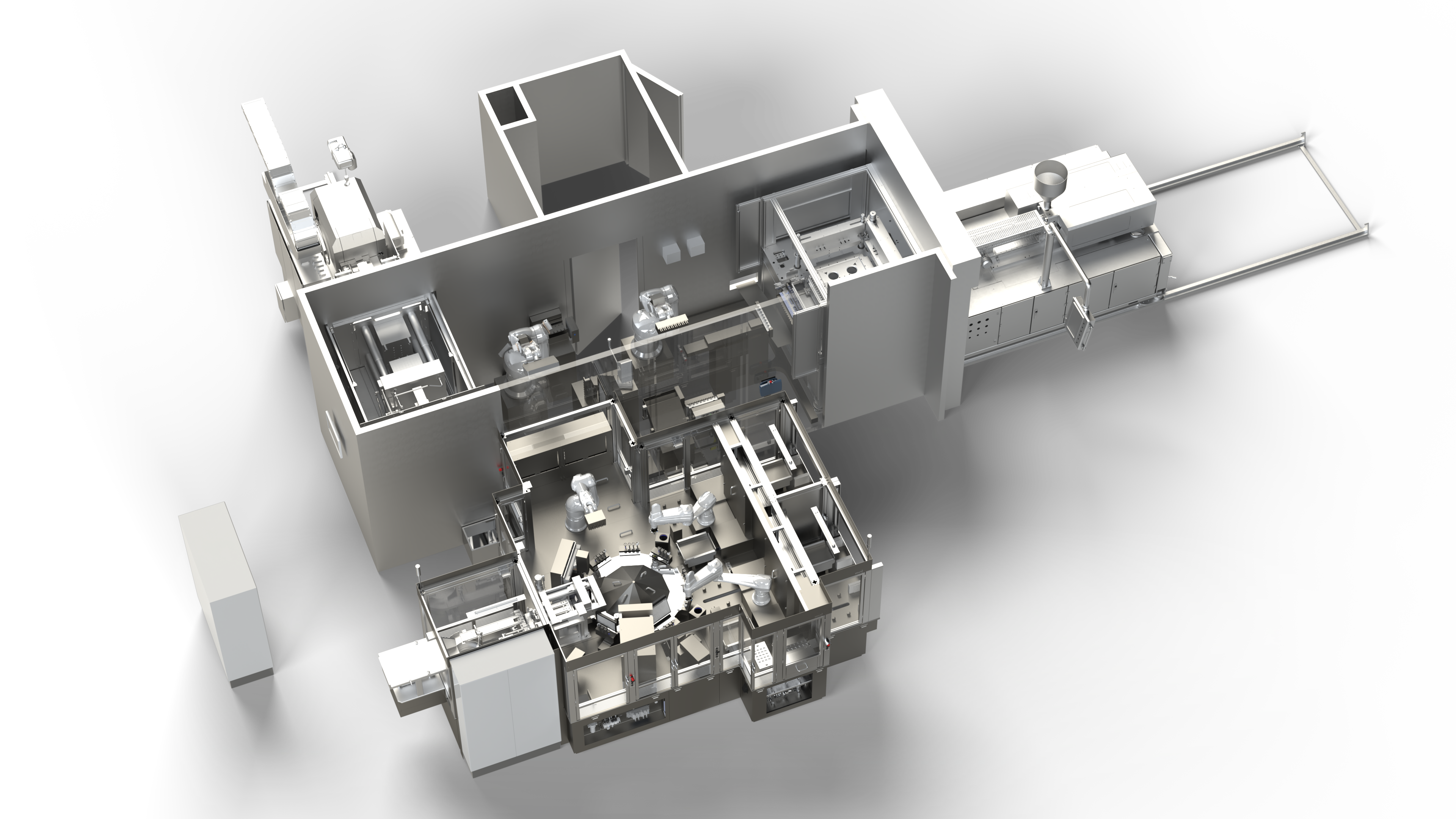

CLEANROOM AUTOMATION: PERFECTION MEETS EFFICIENCY

We are your reliable partner when it comes to customized cleanroom system solutions. With our comprehensive know-how, we meet the highest requirements of cleanroom technology and offer you complete turnkey solutions that are individually tailored to your needs.

Clean rooms and demanding cleanliness standards place special demands on design, functionality, quality, aesthetics and flexibility. We accept this challenge and realize innovative projects in the fields of medical technology, cosmetics and white goods.

Our stainless steel assembly and testing automation systems are specially designed for use in cleanrooms.

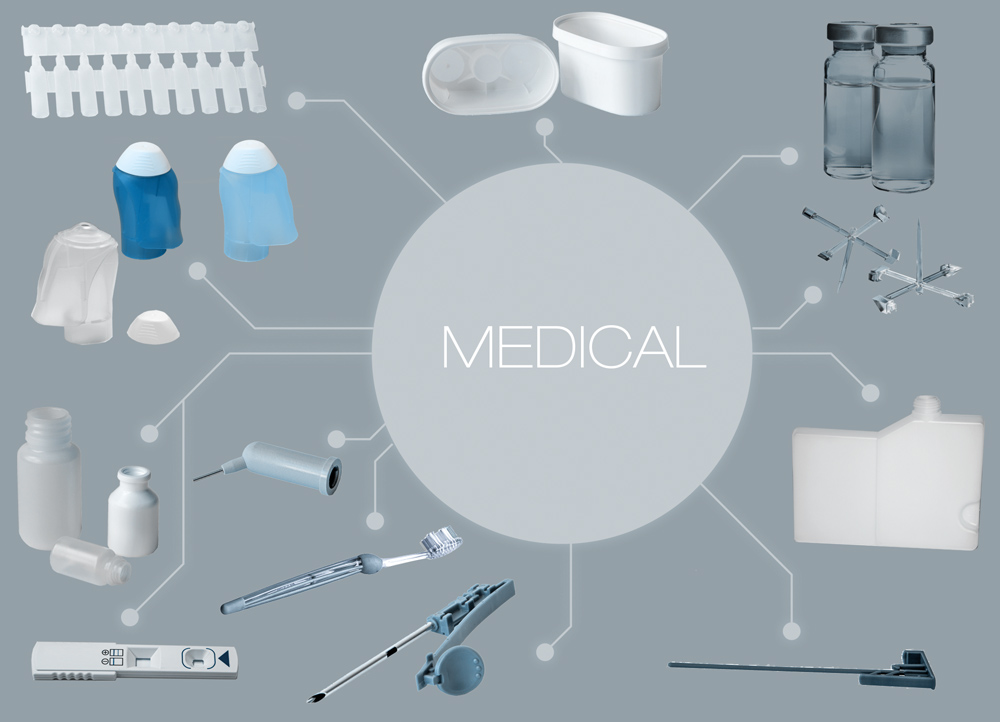

Precision in series production: automation for medical technology

High-speed shaping

Modern injection molding systems enable the fast and precise production of plastic parts with cycle times of just 2-3 minutes. This ensures high production efficiency and consistent quality.

Precise removal

Automated systems ensure gentle and precise removal of the molded parts from the injection mold. This minimizes damage and increases product quality.

Plasma coating

A surface treatment process that improves the adhesion properties of plastic parts. It is often used before printing or bonding to increase the surface tension.

Printing

After shaping, the plastic parts can be printed with information, logos or markings. This is often done directly on the production line for efficient processing.

Camera-based test methods

High-resolution cameras and special image processing algorithms are used to check product quality, geometry and possible defects. This ensures 100% quality control.

Automated packaging

The final step in the production line, in which the inspected and approved parts are automatically placed in suitable packaging. This increases efficiency and reduces human error.